Universal Laser Systems (ULS) are a non-contact solution for many general manufacturing applications. Take an idea from design to finished product in one step and quickly introduce and evaluate changes in a production environment. Because Universal Laser Systems are non-contact, there is no need to maintain tools or compensate for continual tool wear.

Medical Devices

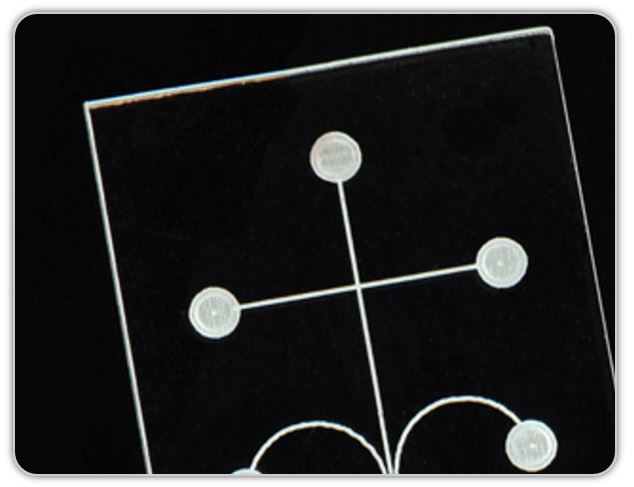

Laser engraved acrylic microfluidic channel

|

|

Universal offers permanent, non-contact, precision laser marking and cutting solutions for medical device manufacturers. Prototyping, channel etching and identification, cutting filter media, and degating are some of the applications available with a laser system. Universal Laser Systems can be used to engrave microfluidic channels into acrylic for laboratory use.

See Medical Disclaimer Below...

|

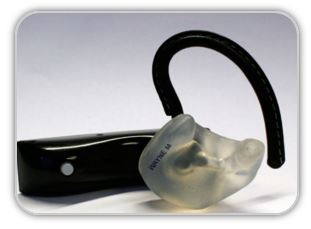

Gaskets

|

|

With a Universal Laser System you can produce gaskets from a wide variety of materials including rubber, cork and plastic.

|

|

Laser cut rubber, silicone and cork gaskets

|

|

Automotive Parts

Laser marked anodized aluminum housing

|

|

Laser mark interior automotive parts for part identification, lot traceability and personalization.

|

Low Volume Production

|

|

Create templates with a laser system to hold identification tags or name plates in place for low-volume laser marking and production. A laser system provides flexibility for producing items in large quantities as well as small lot sizes and single pieces.

|

Laser cut Neoprene gaskets

|

Control Panels

|

|

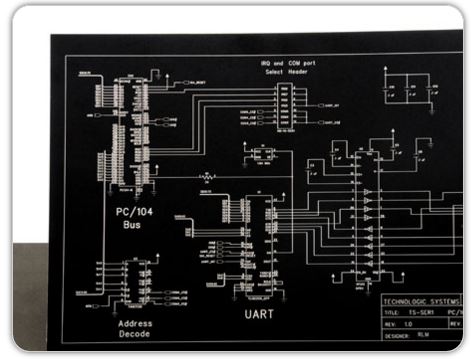

Laser marked anodized aluminum electrical diagram

|

|

Laser systems are great tools for etching control panels and instruments, as well as gauge faces and covers.

|