Universal Laser Systems (ULS) offers laser systems capable of producing 3D models and prototypes much faster than any 3D printer on the market. Laser systems can process thousands of materials in ways traditional methods or 3D printers cannot. Create highly-detailed, three-dimensional, scale models that accurately represent form and space. Lasers also allow you to add dimension and texture by engraving and surface scribing materials. It is as simple as creating a CAD drawing or other graphical file, processing the artwork with the laser system and assembling the finished 3D model. From rapid prototyping to production, laser material processing can be used to improve your product design and optimize your manufacturing.

Here are a few real-world examples showing what multi-material laser processing can do:

General Manufacturing

Laser engraved acrylic microfluidic channel

|

|

Laser cut Neoprene gaskets

|

Package Development

Laser cut cardstock package

|

|

Laser cut and engraved Mylar® package

|

Paper Crafts & Goods

|

Woodworking

|

Laser cut and engraved architectural model

|

Laser engraved and cut wood

|

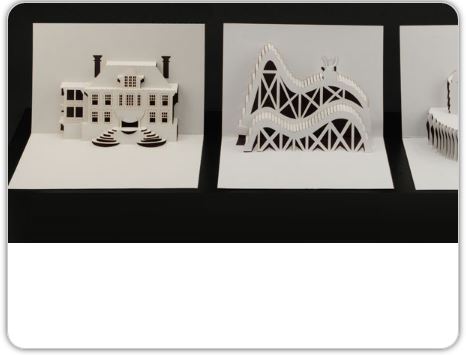

Architectural Models

Laser cut and engraved architectural model

|

|

Presentations take on a new look when created with laser processing. Produce realistic, precision-cut, scale models in-house, quickly and easily. Scribe or cut mat board, acrylics, plastics, wood, paper and most non-metals with clean and defined edges.

|